Thanks to the falling price of 3D printing and the Makers movement, the process of concepting a product has become easier and less costly during the past few years. Add to that, Kickstarter (to fund a product) and Amazon or Etsy (to sell the product), and you have a supply chain disruption that’s perfect for a certain tribe of innovative small business product developers.

But if you’re beyond the concept stage and the backers on Kickstarter love you, where do you turn to get those orders in the hands of your backers? That was the dilemma Tom Gerhardt and Dan Provost and their company Studio Neat faced in 2010. They had to take a crash course in manufacturing options when their first product, a tripod mount and stand for smartphones called Glif, experienced massive Kickstarter success. That was the good news. The challenging news was their need to come up with 5,273 Glif tripods for their backers. Fast.

The conventional wisdom might have the story’s next chapter be them calling China or another country known for low cost and quick-turnaround manufacturing . Not so, say Tom, Dan and a growing number of web-savvy product developers. Working with U.S. manufacturers who have adapted to custom and short-run ways of manufacturing products, small companies like Studio Neat are finding ways to make it in the U.S.A. And that’s important to Tom and Dan.

Dan Provost shared with us why finding and working with a U.S. custom manufacturer helps Studio Neat.

Tom Gerhardt and Dan Provost, designers and founders of Studio Neat. (Photo: StudioNeat.com)

What is the purpose of custom manufacturing? In other words, why choose this option over others?

Custom (or short-run) manufacturing can mean many things, but it’s primary purpose is to produce a product at a smaller scale, like the one we (Studio Neat) operate at. This could mean using a manufacturing technique like 3D printing, finding “normal” manufacturers that are willing to do smaller runs or using an “in-between” service like Protomold. We chose short-run manufacturing out of necessity, as the quantities we have required it.

How did you learn of it? And about it?

We learned about these companies in the standard way: Google. The book Making It by Chris Lefteri was also tremendously helpful in learning about all types of manufacturing techniques.

Would you mind sharing insight into costs?

These vary quite a bit, job to job. A mold for injection molding can cost anywhere from a couple thousand to upwards of $20,000.

How did you find your manufacturer? And why did you choose them?

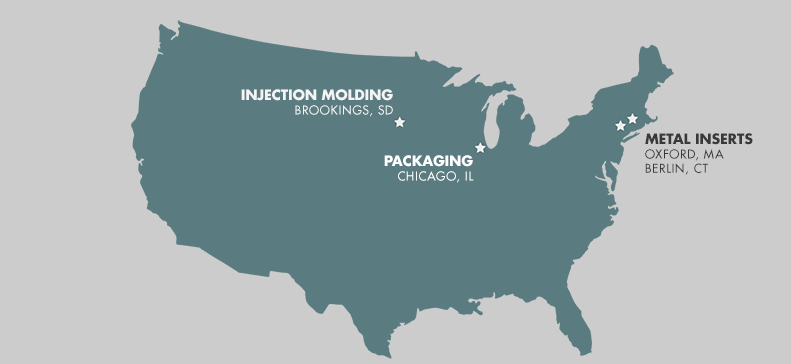

The first company we ever worked with, Premier Source in South Dakota, actually contacted us. They saw our Kickstarter project for the Glif (the iPhone tripod mount and adapter pictured above) and knew that we were looking for a manufacturer. They knew they had the capabilities we were looking for. We ended up getting about six quotes from different manufacturers, but Premier Source really “got” our project, so they seemed like the best fit.

Studio Neat’s popular stylus inspired by the shape and feel of a whiteboard marker, the Cosmonaut. (Photo: StudioNeat.com)

You’ve had several different projects—Glif, Cosmonaut, Neat Ice Kit—have you used the same manufacturer throughout?

We have continued to use Premier Source whenever we can, but often we will need to manufacture objects that differ from their capabilities, such as wood or metal production.

On their website’s product page for the Glif, Studio Neat includes a map showing where each part of the product is manufactured.

You have made a concerted effort to manufacture in the US. Why? Even though you hear, “It’s cheaper overseas,” what are some of the biggest advantages to doing it?

It’s much easier to communicate, visit the factories, etc. For some things, the price difference is negligible from doing it overseas. However, with our latest product, the Neat Ice Kit, there were a couple parts where it simply was not feasible to have them made stateside, so we had to move overseas.

What are your thoughts on 3D-printing and makerspaces? Have you ever used or considered using one? If you did consider it, but eventually decided against it, why?

When we were starting out we used Shapeways often for 3D printed prototypes, and it is a great service. We bought a Makerbot about a year ago and that has been very handy.

What are some of the difficulties you’ve faced in finding a manufacturer? And dealing with them once you have found one?

Finding and dealing with manufacturers is always tricky, and always a learning process. For the most part, the manufacturers we have found are able to do the lower quantities that we require, which is good. (On their website, the Studio Neat guys take a deep dive into all of the manufacturing decisions they made with Glif and Cosmonaut. It’s a must-read for anyone who has an idea for a product but has never taken a concept to production and through to retail.)

What advice would you give to other small business owners/designers looking for a custom or short-run manufacturing supplier?

Google is your friend. Also, don’t be afraid to ask other small business owners and designers who they are using. Once you contact a manufacturer, be up front about your expected quantities so you can start on the same page.

To learn more about the lessons Tom Gerhardt and Dan Provost learned by designing, manufacturing and selling the products of Sudio Neat, you can read their e-book, It will be Exhiliarating: Indie Capitalism and Design Entrepreneurship in the 21st Century.

(Illustration by Rex Hammock, drawn with a Cosmonaut Stylus, SmallBusiness.com)